Analysis of Several Methods of Annealing Treatment in Annealing FurnacePublished by:2023-07-07 Categories:Industry news Viewed by: 1194 times 1. Annealing temperature In many applications of annealing treatment, we only specify the required annealing temperature and then let it cool in the furnace. The reason why Z is prone to failure in the annealing furnace during annealing treatment is the failure to maintain the uniformity of temperature in the furnace. The larger the furnace, the more problematic it is.

2. Process annealing

Due to the phenomenon of work hardening after equal degrees of cold processing in a box furnace, further processing cannot be carried out. Therefore, we must add an annealing step in the manufacturing process to eliminate this unfavorable work hardening phenomenon. This type of annealing treatment is collectively referred to as process annealing. Since we only want to restore the softness of the material and do not care about the microstructure and structural content of the material, in order to reduce the processing cost, we generally use the subcritical annealing mentioned earlier. After cold working, there will be work hardening phenomenon, so that further processing cannot be carried out. Therefore, we must add an annealing step in the manufacturing process to eliminate this unfavorable work hardening phenomenon. This type of annealing treatment is collectively referred to as process annealing. Since we only want to restore the softness of the material and do not care about the microstructure and structural content of the material, in order to reduce the processing cost, we generally use the subcritical annealing mentioned earlier. The common annealing temperature for Z is between approximately 11 to 22 ℃ below Ae. As for temperature control, as long as it can be maintained within the range of Ae.

3. Forging annealing treatment

Due to the frequent processing steps such as cold forming or vehicle models, annealing treatment is an inevitable heat treatment process for forgings. The required annealing process must depend on the material of the forging and the subsequent manufacturing process. Annealing treatment of forgings for cutting - If the forging material needs to have a spheroidized structure for subsequent cutting and forming, we can use a hot forging temperature above the Austenitizing temperature, and then directly send the forging to a furnace with a spheroidizing temperature for spheroidizing treatment after forging. This method can save production time and cost. Annealing treatment of forgings for cold forming - To facilitate subsequent cold forming processing, we naturally hope that the forgings are as short as possible. Therefore, spheroidization treatment is a good treatment. If the shape and material conditions permit, the annealing furnace steps mentioned above are Z feasible treatments. After cold forming, the residual stress of the sintered furnace product should be noted due to cold processing. We should adopt the previously discussed annealing furnace stress annealing treatment to eliminate this situation. |

|

|

About us |

Product Categories |

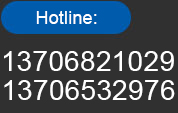

Contact way

|

| Copyright © 2023 Huzhou Dafeng Furnace Technology Co., Ltd all reserved | Web Admin --> >> |