Safety operating procedures for mesh belt sintering furnacePublished by:2023-07-13 Categories:Industry news Viewed by: 880 times The mesh belt sintering furnace, also known as a continuous gas protection bright heat treatment furnace, is mainly used for continuous production of various metal powders such as metallurgical sintering and metal powder reduction. The surface of the products treated with this equipment is bright without oxidation phenomenon. The mesh belt sintering furnace has a novel design, reasonable structure, energy-saving and high thermal efficiency, stable production quality, and safe and convenient use. Easy to operate, no industrial pollution. The temperature control method is advanced, using intelligent temperature control regulating instruments and intelligent controllable silicon. Temperature control accuracy ± 1 ℃. It is progressiveness, reliable, practical and economical in industrial furnaces.

Below, Huzhou Dafeng Furnace Industry Technology Co., Ltd. will explain the safety operating procedures for the mesh belt sintering furnace for everyone

1. Inspection work before heating up

Check if the furnace door is close to the door frame and closed in place. Check if the motor is operating properly and lubricate the transmission system with oil. The instrument worker shall check whether the instruments and meters used are normal and effective.

2. Heating up

Turn on the power switch, set the temperature of each zone according to the process requirements, and start the slow transmission motor of the roller first. When starting to heat up, open the insulation zone, fast cooling zone, and isothermal zone first. When the insulation zone, fast cooling zone, and isothermal zone are evenly heated for half an hour, the workpiece can enter the furnace and begin annealing. According to the calculation of workpiece speed, when the workpiece enters the fast cooling zone, the fast cooling zone is turned on to control the operation of the fan. The instrument used for the fast cooling zone should be set first. Generally, the main control temperature is 10 ℃ higher than the isothermal zone temperature, the upper limit temperature (AH, i.e. the temperature of opening the air door) is 2 ℃ higher than the main control temperature, and the lower limit temperature (AL, i.e. the temperature of closing the air door) is 1 ℃ lower than the main control temperature. According to the set travel time, the slow cooling zone should start heating up 2.5 hours in advance. |

|

|

About us |

Product Categories |

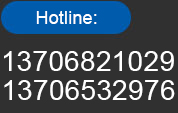

Contact way

|

| Copyright © 2023 Huzhou Dafeng Furnace Technology Co., Ltd all reserved | Web Admin --> >> |