A brief introduction to the annealing furnace processPublished by:2023-07-14 Categories:Industry news Viewed by: 846 times One. Introduction to the annealing process: Annealing is a metal heat treatment process that refers to a heat treatment method that slowly heats metal to a certain temperature, holds it for a sufficient time, and then cools it at an appropriate rate, sometimes natural cooling, sometimes controlled speed cooling.

Two. Purpose of annealing:

1. Reduce hardness, soften workpieces, and improve machinability.

2. Improve or eliminate various structural defects and residual stress caused by steel in the casting, forging, rolling and welding process, and reduce the tendency of workpiece deformation, cracking or cracking.

3. Refine the grain, improve the structure to improve the mechanical properties of the workpiece, and eliminate the tissue defects.

4. Uniform material structure and composition, improve material properties or prepare for later heat treatment, such as annealing, tempering.

In actual production, annealing process is widely used, according to the workpiece requirements annealing purpose is different, annealing heat treatment has a variety of processes, commonly used are complete annealing, spheroidization annealing, stress relief annealing, etc.

Three. Uses of annealing furnaces:

Annealing furnace series industrial furnace is widely used in casting, metallurgy, automobile, aerospace, military, shipbuilding, light industry, electric power and other industries, which can be used for high chromium, high manganese steel castings, gray iron castings, rolls, bearings, steel balls, wear-resistant liners and other metal workpieces for different annealing heat treatment processes.

Four. Annealing furnace working mode:

The annealing furnace is made of square or round furnace structure, the furnace is installed with refractory bricks and aluminum silicate fiber composite insulation, or with a full-fiber insulation furnace lining structure, the workpiece is placed in the furnace, through electric heating, or oil, gas to heat the workpiece in the furnace, under the natural atmosphere or protective atmosphere to heat the workpiece to the required annealing process temperature, after a period of heat preservation, natural cooling or controlled speed cooling. Due to the wide variety of annealing furnace series, there are also different operating methods. The trolley annealing furnace has an independent running loading trolley, the loading and unloading operation is simpler, and can load large heavy-duty workpieces, the pit annealing furnace is suitable for vertical loading of shafts, rods, pipe fittings and other workpieces, annealing heating is not easy to deform.

Five. Classification of annealing furnaces:

1. The annealing furnace is divided into three different types of electric heating, oil heating and gas heating by different heating methods. They are electrically heated annealing furnace, oil-fired annealing furnace, and natural gas annealing furnace.

2. The different furnace structure of annealing furnace is divided into, such as trolley annealing furnace, well annealing furnace, box annealing furnace, and bell annealing furnace.

3. Annealing furnaces can also be divided into vacuum annealing furnaces, controlled atmosphere annealing furnaces and annealing furnaces heated in natural atmosphere. |

|

|

About us |

Product Categories |

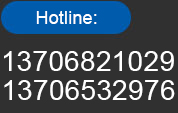

Contact way

|

| Copyright © 2023 Huzhou Dafeng Furnace Technology Co., Ltd all reserved | Web Admin --> >> |